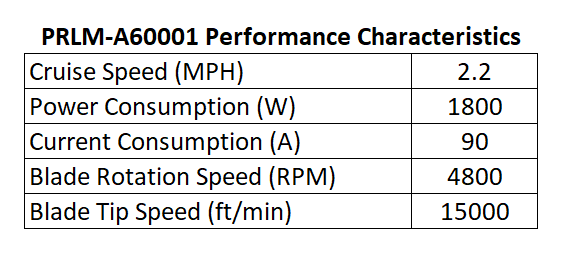

The past few Saturdays I’ve been playing with the robot mower in my backyard. It’s been fun manually driving it around my sprinkler well, flower beds, and garden. The fun ends a lot faster than I’d like: my push mower is 21in wide, but the robot mower is 36in wide, so it doesn’t take very many passes to get most of it mowed.

I’ve spent a lot of time in the backyard for two main reasons: firstly, I want to make sure the mower is safe before I take it somewhere it could hurt a bystander. And secondly, I want to make sure it doesn’t do an embarrassingly bad job at cutting grass.

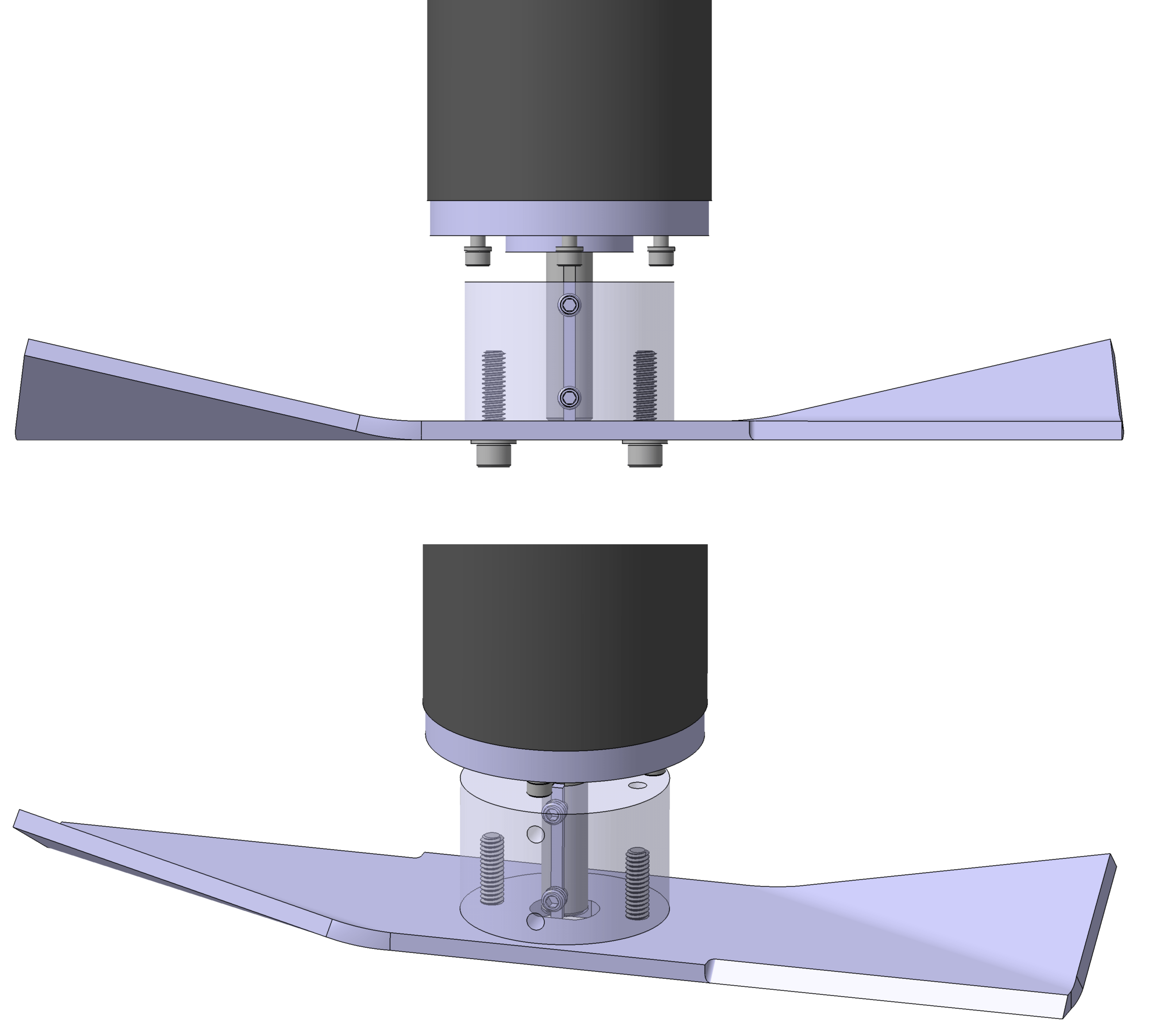

Before I even took the mower out into the backyard, I ran it in my garage with the door down for a good hour or so to make sure the blades were installed securely. The first time I spooled it up was pretty scary. The garage is a giant echo chamber, and so it sounded a lot louder than when I had it running in the backyard.

Once I was satisfied it wasn’t going to vibrate apart, I maneuvered it into my backyard to see how it handled in manual mode, and how good of a job it did cutting my grass. Overall, it performed very well, making grass clippings without any difficulty. I did, however run into two issues:

In manual mode, you can take turns pretty quickly, resulting in some large side forces on the turnbuckle eyes. These turnbuckles were only rated for 36lbf in tension and I wondered how well they’d hold up. Guess we know the answer to that question.

While taking one of those fast turns in manual mode, I had a tire pop off. Yikes! Upon closer inspection, it turns out the nylon portion of the locknuts on the motor shaft were not actually threaded onto the shaft.

In my CAD model I had 1.5 threads engaged. Not great, but enough engagement to where I wasn’t worried about it. In reality, I didn’t get them threaded on all the way. I replaced both locknuts with a split lock washer and a jam nut.

These were good issues to discover in the backyard, where I could easily fix them without much embarrassment.

Satisfied that everything was working well, I loaded up and headed out to the field to try an autonomous mission. My backyard is great for manual mode, but it’s too small to run an autonomous mission.

It’s always good to have goals when you head to the field. For this field trip, I wanted to accomplish the following:

- Practice getting the mower from my garage to the field. With four 35Ah lead acid batteries in the mower, it weighs close to 300lb now. Getting it from point A to point B is turning out to be an art in and of itself.

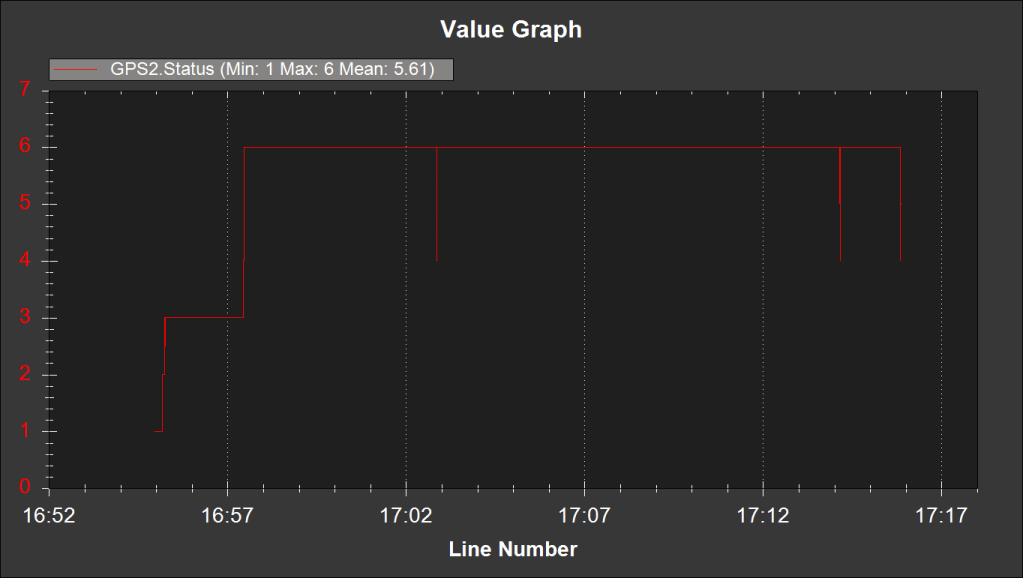

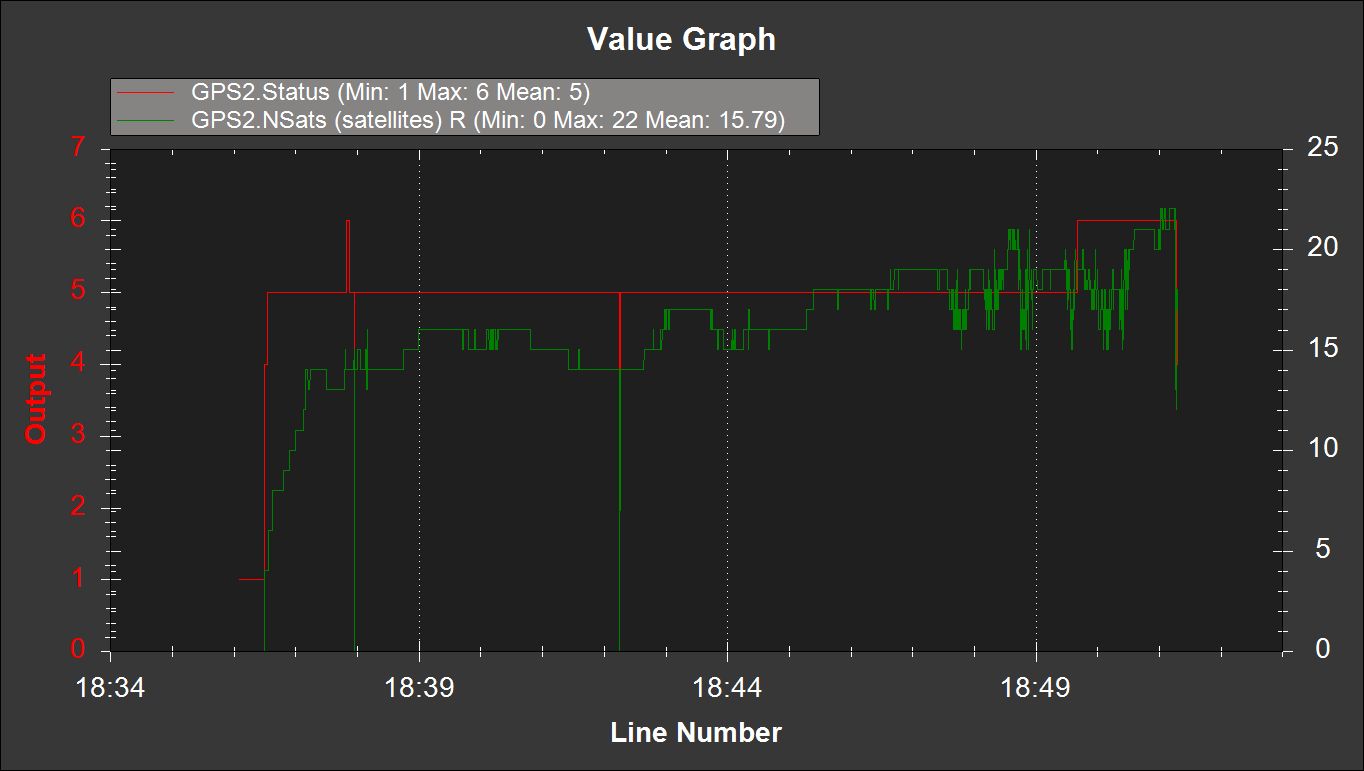

- I made some changes to the ZED-F9P RTK GNSS settings based on comments made on a prior post. I wanted to determine if these changes helped or hurt my ability to maintain an RTK fix.

- Being in a field with tall grass, I also wanted to push the envelope and see what the mower could cut effectively. The homogeneous fescue in my yard isn’t that difficult to cut.

- Collect some general data about the mower’s performance. How much power does it actually use? How hot do the motors get after running for a while? How well does it mow autonomously?

Before I was using the mower deck, I only had two batteries in the battery bay. Loading and unloading isn’t too bad in this scenario: you can pretty easily drive the mower up the ramps and into the bed of my truck. With the other two batteries installed, that process becomes a little sketchier.

The wheel chair gearmotors have a neat little quarter-turn mechanism that disengages the output shaft from the rest of the gear train and lets the wheels spin freely, so I used this feature to push the mower up the ramps and into the bed of my truck. It’s too difficult to precisely maneuver the mower up the ramps and into the bed using the RC transmitter with the added battery weight.

Once in the field, I drove the mower out a safe distance away from the street to let it start working on an RTK fix. I wasn’t worried about absolute position, so I had the RTK base station configured to survey-in its location and used whatever it eventually settled on.

After I had an RTK fix, it was off to the races. I made a mission that was approximately a 100ft square and planned passes that were spaced 30in apart.

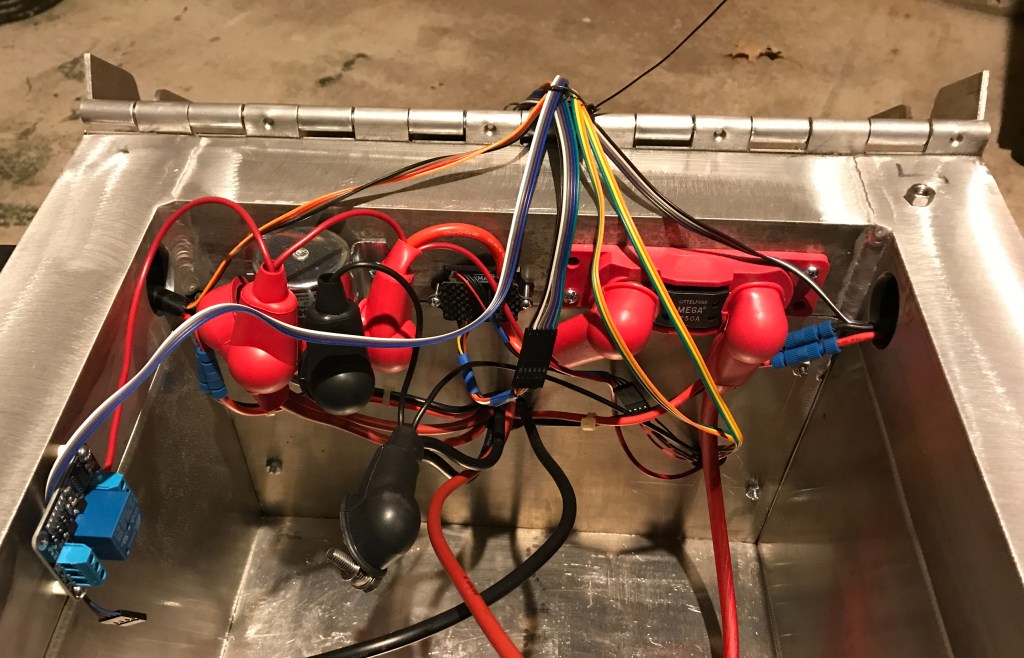

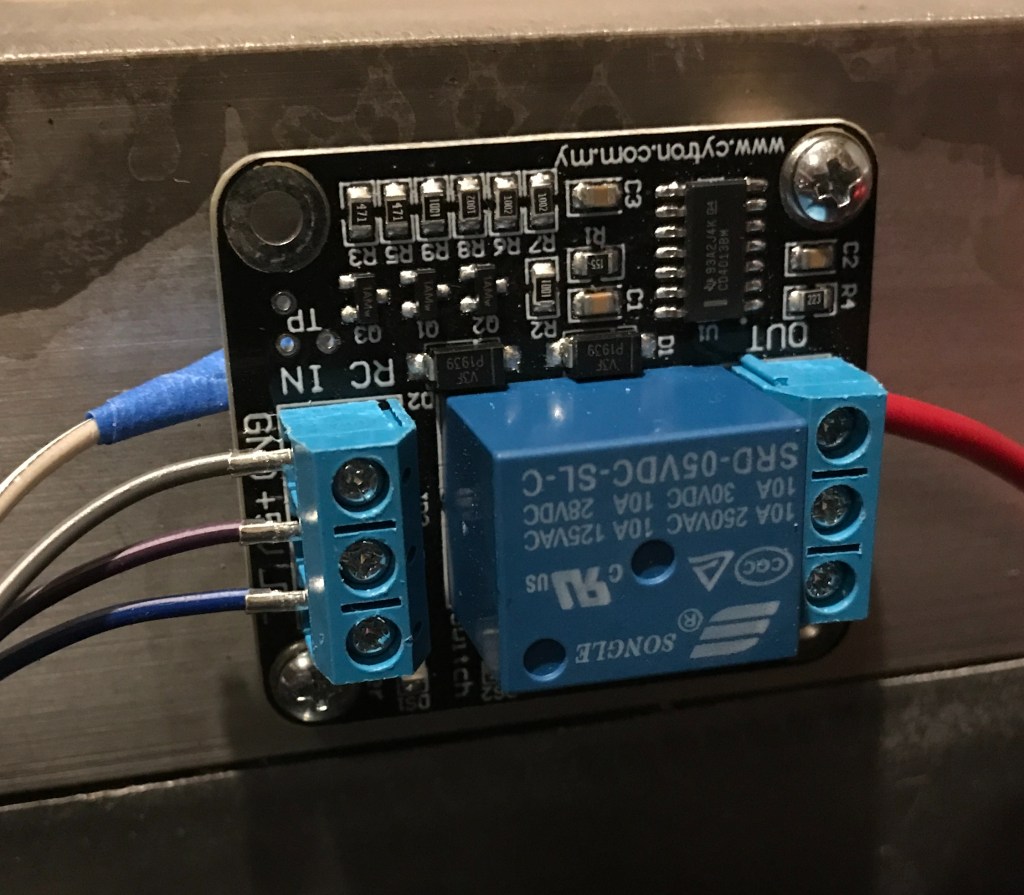

I configured channel 4 on my transmitter, the rudder stick, to control the power to my mower blades. This way it functioned as a dead man switch: if I let go of it, it would spring back to the neutral position. I designed relays inside the power enclosure to engage when the stick was held to the left. To keep the mower blades on, the stick must remain in that position.

After the mower made a few passes autonomously, I turned the blades on. That’s what you see in the video at the top of this post.

If the mower had maintained its position perfectly during the mission, each pass should have overlapped 6in because the mower deck is 36in wide and each pass was spaced 30in apart. Unfortunately, the mower’s position floated around by a fair amount. The un-mowed portions of the field are a result of this position error, which I’ve heard referred to as cross track error.

In some areas, the width of un-mowed grass was as large as 16in. This was a little disappointing. On average it was closer to about 8in. I need to find ways to improve the mower’s position estimate, so I don’t have to tighten up the spacing between passes.

The robot was using the magnetometer for heading, and you can see in the video that after each 180° pivot turn, the mower weaves a little bit as it tries to figure out its heading again. I intend to run another mission in the field soon with the magnetometers disabled to see if this improves the heading. Long term, I will look into using an additional RTK GNSS receiver to estimate the robot’s yaw.

This post is already pretty long, so I’ll make a separate one to review the logs and performance metrics I wanted to measure out in the field.